edited by Catalina Del Castillo

Will AI ever replace your employees?

There is little argument about the difference between human workforce and AI when it comes to accuracy, efficiency and competency. Most of us could agree however, that it is inevitable to rely on better technology to increase production and sales, especially in fulfillment.

From the social distancing doglike robotic dog in Singapore- developed by Boston Dynamics of Waltham, Mass. to the rolling robotic assistant in China developed by Taimi Robotics Technology Co. Ltd. based in Shanghai, this AI technology has drastically helped governments and even the economy in executing successful strategies of fulfillment to help its citizens maintain distance. Some 300 hundred machines in Chinese hospitals helped sterilize wards, deliver medication and check patients’ body temperatures.

So what can you do right now to improve your fulfillment accuracy with artificial intelligence?

Here are 4 reasons you should shift to AI NOW.

2. Automate pick and pick route

3. Automate packaging and shipping

Automate Warehouse Choice

Artificial Intelligence (AI) is the wave of the future and if you are wondering if AI can help you with inventory management - The answer is most definitely! The bigger question for small to medium organizations is the expense.

More than a few companies cannot afford the investments required to implement advance technology or even comport the system process to build on-premises data warehouses. Fortunately, there are systems that provide an all in one software technology that takes care of the back in process at an affordable price. AI used at SkyNexus provides modernized gradient applications that adopt high quality data with a blueprint in data warehouse management.

As the latest report from a featured article by Paul Watson- Gover at Techearti suggests “modern problems require modern solutions- central to the process is automation, as it delivers the flexibility, control and performance required for data warehouse design, development and administration. With an automation-led approach guiding development, data warehouses leave behind outdated methodology and practices. In doing so, it becomes possible to address the shortcomings of traditional approaches where productivity, flexibility, reuse and adherence to standards are much more restricted. “

Inventory management systems are not just for tracking inventory and orders, they should be used to automate many of the processes associated with logistic costs and shipment operations.

Using an inventory management system, you can define a set of rules to automatically determine which warehouse should fulfill which order. This can be to fulfill from the warehouse physically closest to the shipping address, or to fulfill from the warehouse with the most available in stock. Whatever your set of rules is, automating the warehouse choice will simplify the process.

Automate Pick and Pick Route

When it comes to implementing an automating ordering process, it is also equivalent important to maximize efficiency in the ordering element. More and more companies are understanding that AI is the way and maybe the only way of the future for sustainable logistics businesses.

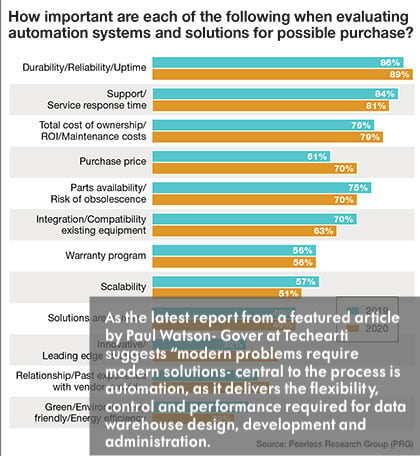

On just last year’s survey by Peerless Research Group (PRG) of Modern subscribers, “ it’s clear that automation is breaking through the barriers as more organizations invest in new technology for their facilities. Modern Material Handling’s “2020 Automation Solutions Study” supports this assumption, proving just how important automation’s role is in the modern warehouse or DC.

From the survey, respondents shared their views of important automation solution features, the extent to which they have implemented automation in their warehouses, and of course, how Covid-19 will impact their future plans. Of the 225 readers who participated in the study, 31% are employed by companies with less than $10 million in revenues and 18% are with firms that fall into the $10 million to $49.9 million category. The bulk of respondents (66%) work for manufacturing firms, while 36% work in a non-manufacturing sector.”

How orders are picked from the shelves is one of the best ways to ensure efficiency in the warehouse and most in the industry are jumping on board with the evident pivotal move on implementing AI to their processes. When you are able to schedule waves (automated group picks) you allow for more orders to be picked at once and this allows for fast and efficient ways to speed the route of packages to fulfillment and delivery.

Drop Ship Automate Packaging and Shipping

Tied together with pick and route, AI allows you to customize a predefined set of rules. With an order management system (OMS) it can be determined which packaging should be used for each order. This will take the guesswork out of the packaging process and ensure more uniform results. In addition, AI can determine the correct shipping speed for each package.

Shipping Mappers

There are basic principles that a stream mapping system delivers to ensure that you have an accurate overview of costs and the most affordable channels to protect your shipping budgets.

Aligned with automated systems in order amounts, pick up and deliveries, a high quality and advanced system should provide a fully functional shipping management system to price check the different carriers and determine the best cost- effective method.

SkuNexus is a fully customizable commerce operations platform. Click here to learn more!

Using SkuNexus, a fully customizable commerce operations platform. Using AI, SkuNexus can help you automate most of your warehouse operations, from picking to packing and finally to shipping.

Click here to see for yourself!